Steam & Condensate

Steam Trapping and Tracing Equipment

Armstrong’s piping solutions are custom-engineered for easier maintenance, improved reliability and performance, and quicker updates and changes. From steam traps, trap valve stations and Pressure Reducing Valves (PRVs) to steam calculators, condensate pumps, control valves, air vents and more—Armstrong has it all.

Steam Traps

Armstrong offers effective steam trapping for your application, industry and lifestyle of installation, including:

- Bimetallic superheat steam traps

- Clean steam thermostatic steam traps

- Disc steam traps

- Dual orifice steam traps

- Float and thermostatic steam traps

- Inverted bucket steam traps

- Steam trap options and connectors

- Thermostatic steam traps

- Thermostatic wafer steam traps

- Trap valve stations

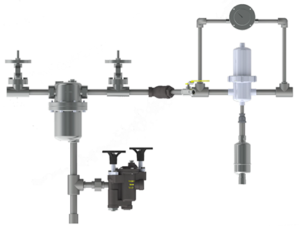

Steam Tracing Systems

Steam Distribution and Condensate Collection Manifolds from Armstrong International streamline your tracing applications by combining all of the necessary parts—steam traps, steam tracing manifolds, and valves—into one small, conveniently placed assembly. This lowers installation costs.

Automatic Differential Condensate Controllers

The automatic differential condensate controllers (DC) from Armstrong International are intended to work in gravity drainage applications where higher velocity will promote condensate drainage or in situations where condensate must be lifted from a drain point.

Steam System Monitoring

Armstrong International offers top-notch, market-leading solutions for steam system monitoring, including steam quality and essential trap performance or your complete steam trap population.

Wireless Monitoring

Armstrong provides cutting-edge wireless and battery-free systems that allow precise, real-time monitoring of your important process traps or your complete population of steam traps. You are immediately informed of any faults, allowing you to fix or replace broken traps before they seriously impair the steam quality. Payback for replacing failed traps quickly is substantial. SAGE® and all of Armstrong’s wireless monitoring systems are in constant communication.

Automatic Steam Quality Monitoring

Compared to conventional manual techniques, Armstrong’s Steam QM® automatic steam quality monitoring is quicker, more precise, and far safer. For the global healthcare, food, pharmaceutical, manufacturing, culinary, and other industries, our Steam QM® Series offers dependable, cutting-edge solutions for calculating and communicating the dryness fraction of steam, amount of superheat present, concentration of non-condensable gases in steam, and more.

Steam Filters

Armstrong’s stainless steam filters are made to filter steam and are ideal for both process steam and food steam. They produce low differential pressure at high flow rates. It is usual practice to regenerate steam filter components in order to lower pressure drop, get rid of settled pollutants, and stop permanent contamination buildup. For a variety of uses, including aseptic packaging, breweries, chemicals, dairies, electronics, food and beverage, medicines, and plastics, Armstrong offers steam filtering. Armstrong can offer the filtration that your business and industry need, whether it is for clean steam in sanitary applications or industrial steam.

Strainers

To satisfy the majority of pipeline straining requirements, Armstrong offers strainers in a variety of sizes and materials. All of these strainers are produced to Armstrong’s high standards and come with a warranty against manufacturing or material flaws. Cast iron, carbon steel, chrome-moly, forged steel, stainless steel, and bronze are the materials that can be used to make Armstrong Y-type strainers. Screwed, socketweld, and flanged connection types are available. There are stainless steel Armstrong T-type strainers available.

Condensate Recovery

With the aid of Armstrong’s condensate recovery technologies, your steam system’s valuable Btu may be fully utilized. Condensate leaving a trap comprises roughly 20% of the heat energy transferred at the boiler in the form of sensible heat, depending on pressure. By assisting you in lowering costs associated with fuel/energy consumption, boiler water make-up and sewage treatment, and boiler water chemical treatment, our condensate recovery systems are intended to provide efficiency and savings.

Air/Gas Vents

The float-type air/gas vents from Armstrong rapidly adapt to changes in gas flow and pressure. We can remove gas from liquids with specific gravities as low as 0.40 and pressures up to 2,700 psi (186 bar) using our air/gas vents. The simple design and high-quality mechanism make operation trouble-free and maintenance minimal, and operation is entirely automatic. Applications include solvent filters, centrifugal pumps, water service lines, water storage tanks, hydronic heating systems, and related machinery. large range of sizes, end connections, and building materials are available.

When it comes to equipment where air can collect in secluded areas of chamber-type heat-transfer devices like jacketed kettles, retorts, vulcanizers, and jacketed sterilizers, Armstrong offers thermostatic air vents.

Pressure and Temperature Controls (Regulators and Control Valves)

With the aid of Armstrong’s condensate recovery technologies, your steam system’s valuable Btu may be fully utilized. Condensate leaving a trap comprises roughly 20% of the heat energy transferred at the boiler in the form of sensible heat, depending on pressure. By assisting you in lowering costs associated with fuel/energy consumption, boiler water make-up and sewage treatment, and boiler water chemical treatment, our condensate recovery systems are intended to provide efficiency and savings.

Liquid Drainers

The dependable liquid drainers from Armstrong are designed to remove liquid continuously, automatically, and consistently even when there is oil, grit, or dirt present—without wasting any air or fuel. Our liquid drainers require no adjustment or maintenance and have a long, trouble-free operational life. They are also simple to repair. Condensate drainers, compressed air drains, air traps, compressed air traps, float traps, water traps, and dump valves are other names for liquid drainers.

Radiator Products

Armstrong International is a top provider of radiator products, meeting the distinct requirements of lodging establishments, business structures, educational institutions, and pretty much everyone else that requires steam or hot water radiators for building heating.

To accommodate the vast range of needs in this niche market, our radiator products are available in a variety of sizes, body patterns, connection kinds, and body materials. All radiator products and parts are produced in accordance with Armstrong’s stringent standards, are warranted to be free from flaws in manufacturing and materials, and are supported by internal experts available to assist with challenging or uncommon requirements.

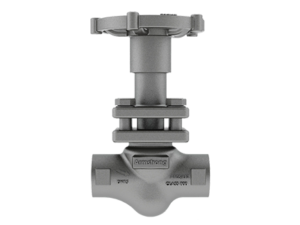

Piston Valves

The maximum operating pressure and temperature of Armstrong Piston Valves, which are full port forged steel isolation valves, are 136 barg (1973 psig and 427°C/800°F, respectively). Even at higher temperatures, the burnished piston and metal-reinforced graphite rings provide leak-proof cutoff while extending operational life. It is simple to change every component of a sealing valve in-line.

Our piston valves are made to assure activation even after extended periods of inactivity and provide long-term, fire-proof functioning. They are also resistant to cavitation. Available in socket weld, BSPT, and NPT end connections, these fittings are excellent for saturated and superheated steam, as well as hot water applications. On request, flanged ends can be provided. sizes that are compatible with API, ASME, IBR, and DIN standards range from 15mm/1/2″ NB to 40mm/1-1/2″ NB.