Drive Production Efficiency with Collaborative Robots

The demand for flexible, efficient automation is increasing across industries. Collaborative robots (cobots) boost productivity and safety by working directly with your team, automating repetitive tasks without disrupting workflows.

At CB Pacific, we offer expert solutions to unlock the full potential of cobots, providing scalable options for applications such as machine tending, assembly, and more. Whether optimizing existing operations or implementing new systems, cobots deliver rapid ROI and long-term operational benefits.

Transform Your Operations with Cobots

Your Most Reliable Production Partner

Cobots are designed to work safely alongside people, bringing flexibility and efficiency to the production floor. Unlike traditional industrial robots that require safety cages or complex setup, cobots are built for direct collaboration—simple to program, easy to adapt, and ideal for repetitive, physically demanding, or hazardous tasks.

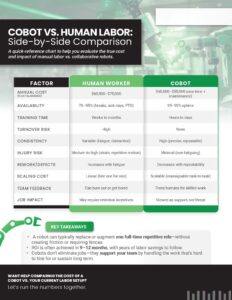

Across industries, cobots are helping companies overcome rising labor costs and safety challenges. They improve productivity, enhance workplace safety, and increase operational efficiency—allowing your team to accomplish more with fewer resources.

Unlock the ROI of Cobots

Adopting cobots doesn’t just improve performance—it pays off quickly. Businesses that implement cobots experience measurable returns through reduced labor costs, minimized downtime, and higher throughput, making automation a smart long-term investment.

Uncover the Real Value of Automation — Calculate Your Cobot ROI

Cobots in Action: Harness the Power of Collaborative Robots for Your Business

Cobots fill the gap between manual labor and full automation, providing a versatile solution for businesses tackling challenges like labor shortages, rising costs, and the need for consistent quality. They offer precision, scalability, and seamless integration, enhancing efficiency while empowering your team across diverse applications.

Explore key cobot applications designed to optimize your operations and drive results.

Machine Tending

Cobots automate the loading and unloading of machines like CNCs and presses, improving operational efficiency, reducing human error, and minimizing operator fatigue for more consistent and reliable production.

Palletizing

Cobots optimize palletizing by efficiently stacking products or materials onto pallets, enhancing consistency and reducing manual labor, especially in high-volume production environments.

Pick and Place

Cobots excel in pick-and-place operations, quickly and accurately transferring components or products to various locations on the production floor, improving workflow efficiency.

Assembly

Cobots enhance assembly lines by automating repetitive tasks like part assembly and screwdriving with high precision, boosting speed and minimizing errors in the process.

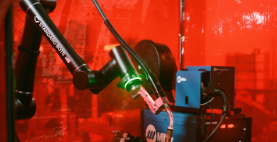

Hazardous Environments (C1D1)

Cobots are designed for hazardous environments, such as C1D1 areas, where they can safely manage dangerous materials or processes, minimizing risk to human workers.

Welding

Cobots automate welding tasks with precision, delivering consistent, high-quality welds for spot and arc welding, especially in small-batch and custom production runs.

Lab Automation

Cobots streamline repetitive laboratory tasks like sample preparation and testing, enhancing efficiency, consistency, and accuracy while allowing staff to focus on more complex, value-added work.

Inspection

Cobots with integrated vision systems and sensors inspect products for defects and quality issues, ensuring consistent quality control and minimizing human error.

Cobots from Leading Manufacturers -

Powered by CB Pacific

At CB Pacific, we offer top-tier collaborative robots from Standard Bots, delivering cutting-edge automation solutions for every application and budget.

We help manufacturers unlock the full potential of Standard Bots cobots with turnkey solutions, from design and integration to ongoing support. Our team ensures a smooth setup and minimal downtime, getting you up and running quickly.

Standard Bots

Explore Standard Bots’ user-friendly, American-made cobots, engineered for flexibility, ease of use, and seamless integration into your operations.

New legislation just made robotics the hottest investment!

On July 4, 2025, Congress passed H.R.1 (Public Law 119-21), reinstating 100% first-year bonus depreciation for qualified production equipment. That means robotic systems – including robots – can now be fully deducted in year one, accelerating ROI more than ever.

Cobot FAQs: Get All the Answers Here

A cobot is designed for safe collaboration with humans, working alongside them without the need for physical barriers. Cobots are typically more compact, easier to program, and cost-effective, making them ideal for a wide range of applications.

Yes, cobots are designed with safety as a top priority. Equipped with force-limiting sensors and emergency stop functions, cobots can slow down or stop completely if they detect a person nearby, ensuring safe operation in shared workspaces.

To choose the ideal cobot, assess the tasks it will perform, including weight and reach requirements, the desired level of automation, and your budget. This will help you determine the best cobot to optimize your operations.

Most cobot systems are up and running in just a few days, not months. With CB Pacific’s turnkey setup and training, you’ll experience a quick and seamless installation, minimizing downtime and accelerating your start.

Cobots are widely used across industries such as manufacturing, packaging, metalworking, electronics, food and beverage, and more—any sector where efficiency, safety, and precision are essential.

Yes, cobots are highly portable and can be easily reprogrammed for different tasks, making them perfect for dynamic production environments that require flexibility.

Cobot Knowledge Hub

Stay informed with the latest advancements and best practices in collaborative robot. Click on the resource to start your download.